an industrial safety & marine products distribution company

an industrial safety & marine products distribution company

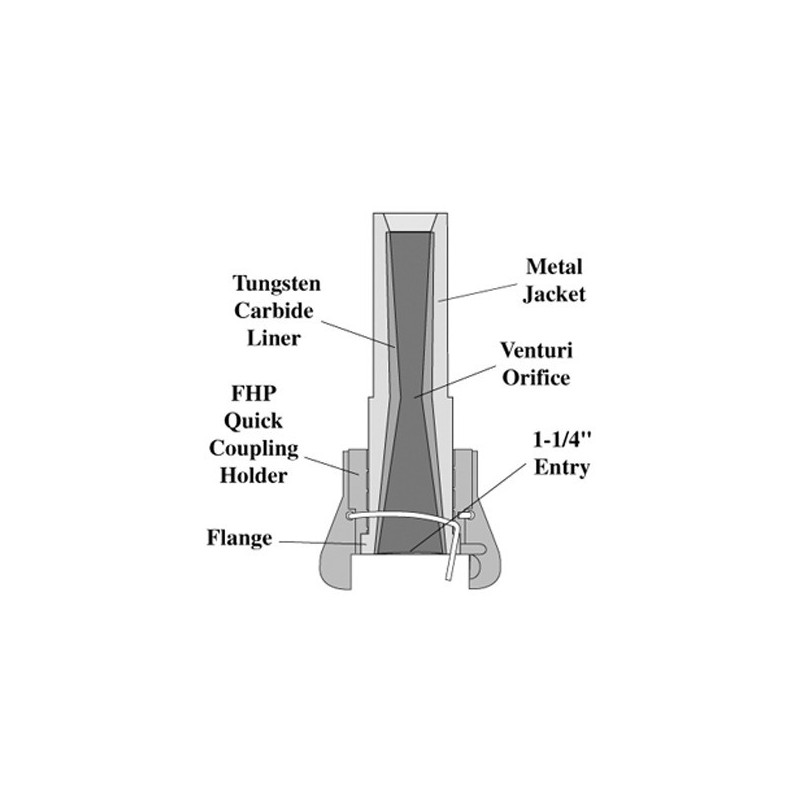

Short Venturi: CJD

Long Venturi: CSD, TXD, SDX, CXD

A blast nozzle accelerates the air and abrasive as the mixture exits the end of the hose. The taper and length of the nozzle's inlet and outlet determine the pattern and velocity of the abrasive exiting the nozzle. The composition of the liner material determines its resistance to wear.

Secured

Secured

Fast Delivery

Fast Delivery

7 days Return

7 days Return

Requirements for Operation

Nozzles are sized by the diameter of their orifices in 1/16-inch increments. A No. 2 nozzle has a 2/16-inch (1/8-inch) orifice, a No. 3 nozzle has a 3/16-inch orifice, etc. The size of the nozzle orifice determines abrasive and air consumption. Air consumption is measured in cubic feet per minute (cfm) at a given pressure.

When choosing a nozzle, consider the amount of available air in cfm, the capacity of the blast machine and the inside diameter of the piping, and the blast and air hoses. For optimal performance, these elements must be compatibly sized.

If too large a nozzle is used, low blast pressure and rapid wear on the blast hose will occur. If too small a nozzle is used, smooth media flow will be difficult to achieve.

Description of Operation

The operator inserts the nozzle washer into a contractor-thread nozzle holder and screws in the nozzle, turning it by hand, until it seats firmly against the washer.

With all related equipment correctly assembled and tested, the operator points the nozzle at the surface to be cleaned and presses the remote control handle to begin blasting. The operator holds the nozzle 18 to 36 inches from the surface and moves it smoothly at a rate that produces the desired cleanliness. Each pass should overlap slightly.

The operator must replace the nozzle once the orifice wears 1/16-inch beyond its original size.

Advantages

Replacement Parts

For flanged nozzle use coupling lock-springs

product appraisal

This is the best product I ever got here in Nigeria, it actually served me perfectly well, all thanks to industries safety Nigeria for always supplying quality products.